Hunkeler – Powerful Web Finishing Systems

Hunkeler develops and supplies innovative solutions for continuous feed paper processing throughout the digital print process: Modular, high-performance systems that present the paper to the digital press and then further process the printed paper through to the end product. Completely integrated systems are produced in close partnership with the leading digital press manufacturers. Centrally controlled, these systems guarantee the highest productivity, flexibility and process reliability.

- Publishing

- Transactional

- Direct Mail

- Commercial

- Pharmacuetical

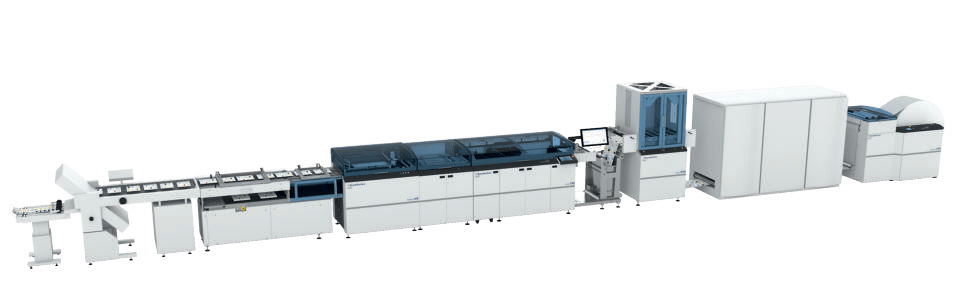

Starbook Plowfolder book solution with Book Sorting Module BSM

Starbook Plowfolder book solution with Book Sorting Module BSM

The new highly automated Hunkeler Starbook Plowfolder book solution allows for highly economical production of digitally printed books from Book of one. Fully variable page count and variable spine lengths from book to book and semi-automatic changeover of different folding patterns (in about 3 minutes) make for a great format flexibility for every run length.

Excellent book block quality with perfectly straight, square and flatbook blocks make it the quintessential solution for softcover and hardcover books alike. Ease of operation, low maintenance, media flexibility, and the ability to deliver single book blocks at a rate of up to 2000 deliveries (stacks or books) per hour in perfect FIFO sequence (First in- First out) makes it the star of the Hunkeler book solution portfolio.

Ask us about Starbook and Book Sorting Module BSM – get in touch!

Options:

- Book Sorting Module BSM

- Book block transport system

- DynaCut

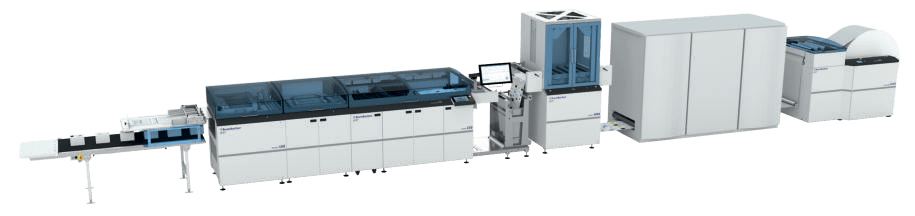

New Starbook Plowfolder book solution with Media Changer RX8

The Starbook Plowfolder produces pre-glued book blocks for softcover and hardcover books for further processing in perfect binders based on 4, 6, or 8 page signatures. With the Media Changer RX8 for automatic roll splicing, we are introducing our latest solution in our unwinder series. In addition to the conventional nonstop feeding of papers of one quality, the RX8 can also be used for printer-controlled selection between two different papers. This new solution allows the nonstop batch production of books with different paper.

Options:

- Book Sorting Module BSM

- Book block transport system

- DynaCut

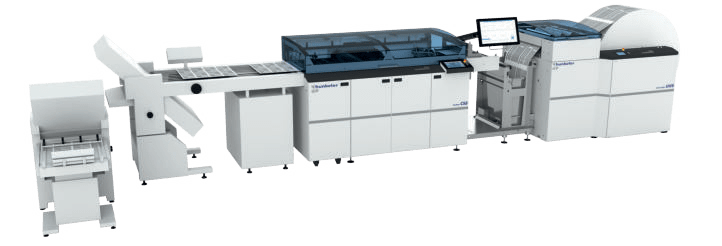

New Starbook Webfolder book solution with Media Changer RX8

The new Hunkeler Starbook Webfolder book solution is perfectly situated for softcover or hardcover book blocks and catalogues based on 4 page signatures. Fully variable page count and variable book spine lengths form book to book and an economical price tag make it the second star in the Hunkeler books portfolio. The modular Book Delivery BD8 garuantees anexcellent book block quality with perfectly straight, square and flat book blocks and a performance of up to 2000 stacks per hour in FIFO sequence.

The system is fed by the Media Changer RX8 that allows printer supported media roll changes with automatic roll splicing of different papers on-the-fly.

Options:

- Book Sorting Module BSM

- Book block transport system

- DynaCut

Plowfolder book solution

Outstanding features of the Plowfolder book solution are the on-demand production of book blocks with variable page count and format lengths (when using the DynaCut function) as well as perfectly glued book blocks for reliable finishing in the perfect binder. In addition to processing, 4, 6, and 8 page signatures into book blocks, it is also possible to produce loose sheet stacks for thread sewn books. The plowfolder book solution can be useed nearline as well as inline at a printing system or perfect binder.

Options:

- DynaCut

- Tracking

Flyfolder book solution

The flyfolder book solution is an equally innovative and revolutionary simple concept for modern Book-On-Demand production. The system switches on-the-fly between 4page and 6page signatures without stopping production. Thanks for perfect book block stacks in the Starwheel delivery, a reliable finishing in the perfect binder is guaranteed. The fully automated format changeover is performed on the fly without any manual intervention.

Options:

- Front/Back Verification

- Tracking

Roll to Stack solution with longsheet-tray

The modular Hunkeler Roll to Stack solution for stacked sheet output with continuous feed digital printing systems. Innovative nonstop stacker with rotary single cut sheeter or variable chip out double cutter for full-bleed products. For example, cleanly offset-stacked sheets can be output for further downstream processing, such as perfect binding. Loose sheet offset stacks from 1-up to 4-up production.

Options:

- Linear Perforations for book sgantyures or tear off perforation

- Autoregister

- DynaCut

- Tracking

Roll to Buckle Fold solution

Production of variable signatures from a roll for book production, catalogues and magazines. Signatures can trhen be fed to a gathering machine, a saddle stitcher or a thread sewing machine. The dynamic and variable cross cutting unit in the Length + Cross Cutter CS8 can be equipped either with two knives for chip out or with one cutting knife and one perforating blade for dynamic fold perforations. This allows the production of high quaity variable and flat signatures.

Options

- DynaCut

Roll to Roll Solution

The Hunkeler roll to roll solution with different configurations for continuous feed digital presses. High speed Hunkeler unwinders and rewinders ensure efficient, productive downstream processing in the transactional, direct mail, print-on-demand and packaging segments, coupled with inserters and other finishing systems.

Roll to Fan Fold Solution

The modular Hunkeler roll to fan-fold solution with optional punching and perforating. This efficient workflow solution can reduce paper and logistics costs in digital print and mailijng inserting environments. Reliable, inline high-speed operation with continuous feed printing systems in a space saving package with modular options that include a stack cart system, high capacity stacker, and web inspection.

Roll to Stack Solution

High performance Gen8 finishing line for the roll to stack production with CS8 cutting module, seperation module and LS8 stacking module. Web widthsof 22.5inches will be processed at 180 m/min. DynaCut function for variable-format production allows cut-off length changes while running. Gen8 technology is ready for future printing speeds. Reliable processing of demanding products in full colour on coated and uncoated standard paper, from lightweight to heavy-weight grammages. The new Hunkeler Workflow Manager provides user-friendly and convenient operation of the production line.

Non Stop Roll to Roll Solution

Nonstop roll to roll solution at high production speeds up to 243m/min. On -the-fly roll change on the Roll Splicer RS8 and Turret Rewinder TR8. Nonstep roll change in a wide variety of paper weight ranging from 50 to 300 g/m. Increase in productivity of up to 30% compared to manual roll change, depending on print speed and roll length.

Roll to Buckle Fold Solution with Stacker LS8-30

Production of direct mails and selfmailers from preprinted roll to folded end-product. Dynamic linear and cross perforating, dynamic cross scoring, static liner scoring in the Dynamic Processor DP8 with optional dynamic punching. The paper web is liner merge or fold, registered superimposed in a Web Folder WF8. Cross cut and chip out in the subsequent Length + Cross Cutter CS8. Stacking of the sheets in the Stacker LS8 or transfer in the sheet overpass of the Conveyor Belt TB8 into the buckle folder.

Roll to Buckle-Fold Solution with Optional Stream Delivery

Production of Direct Mailings with coupons and included reply cards. Dynamically controlled cross and verticle perforations or scoring in a Dynamic Processor DP8. Subsequent cross cutting in the Length + Cross Cutter CS8. Double cross-cutting cylinder for chip out printed materials with full bleed motifs or for and optional cross perforation. Transfer of the sheets to a buclle folder or alternative output to the new Stream Delivery by rolling away the folder and attaching the moveable Stream Delivery

Roll to Stack solution with Stacker LS8-30

High-performance Generation 8 finishing sol,ution for the roll to stack production. DynaCut function for variable format production allows cut-off length up to 762mm (B2+ Format) changes while running. Reliable processing of demanding products in full-color on coated and uncoated standard paper, from lightweight to heavyweight grammages. Depending on the format, productions from 1-up to 4-up impositioning are possible.

Roll to Stitch solutions

Depending on the configuration, partner solutions can be used to produce either loose leaf stack for perfect bound books or wire stitched brochures – talk to us about the possibilities. The central components are the Length + Cross Cutter CS8 and the sheet overpass on the Conveyor Belt TB8. Following the cross cut, either the open signatures are trabnsferred for the inline stitching process or stacked on the Conveyor Belt TB8 for nearline book production. The moveable sheet overpass aloows for fast and simple changeover between the two processes.

Roll to Buckle-Fold Solution

Production from the roll to the finshed folded package leaflet. Different end formats up to 762mm format length (B2+Sheets) possible. As an option, single-sheet stacks up to a height of 250mm can be stacked or single shets can be fed to a folding unit via the sheet overpass. In the Length + Cross Cutter, inkjet printer colour bars can be cut out automatically and the format length can be changed dynamically from sheet to sheet (DynaCut). In the Separator SE, sheets can be offset laterally in the run at full speed.