Friedheim has the exclusive distributorship for Young Shin Die Cutters in the UK & Ireland, it has been confirmed. From the province of Deagu, South Korea known for its precision electronics manufacturing, Young Shin Industries is an internationally recognized manufacturer of premier flatbed die cutting equipment specifically designed for the folding carton, corrugated and POS/display industries.

Friedheim’s Converting Division, led by John Harrison, will be focusing on the GIANT Series of semi-automatic die-cutters. Seeing clear growth in the corrugated and POS/display industries Young Shin and Friedheim were keen to come to an agreement and provide direct supply of this in-demand series to UK businesses.

With up to 60% market share of packaging substrates, the corrugated/POS sector has largely escaped the pressure we see in the print industry and provides a buoyant area of growth to players both new & existing in corrugated/POS production.

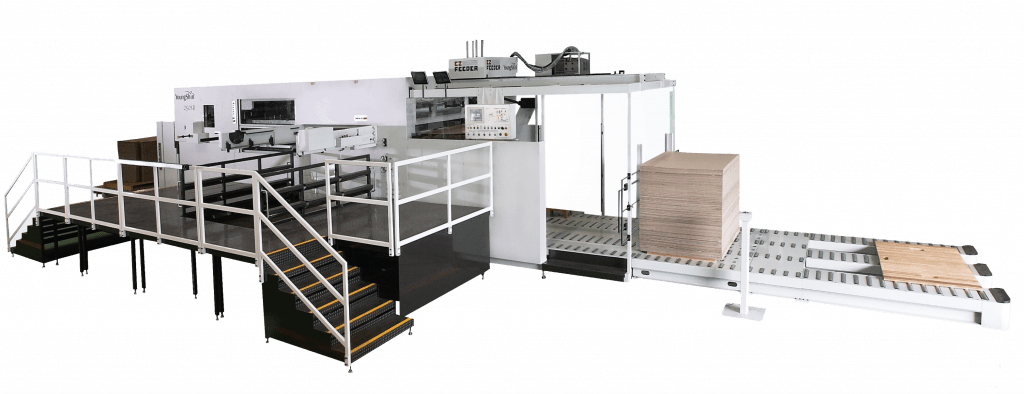

Priding itself on it’s high build quality and extremely low cost of ownership, the GIANT series is a proven solution, with more than 50 existing installations across the UK and Ireland. The popular GIANT 170S die cutter can accommodate E, B, A, AB Flute corrugated board from 1.5mm to 11mm at speeds of up to 3,000 sheets per hour (sph). Other available machines in the GIANT series can reach speeds of 4,200sph and cover sheet sizes from a minimum of 300 x 150 mm, up to a huge 2,500 x 1,700 mm.

The GIANT’s offer precise centre-line technology with quick and easy setup of the die board using the centre block. The unit’s optional EZ-Feeder that automates the feeding and conveying systems, feeds even thin sheets with flawless consistency. An innovative ‘air-floating’ device provides easy withdrawal of the cutting plate for optimum operator efficiency, creating rapid setup and changeover times

Young Shin Industries has earned industry reputation as a global leader within the die cutting and finishing industries. The firm’s superior design and engineering integrates highly-recognized components from Siemens, Allen-Bradley/Rockwell Automation, SEW Eurodrive, Becker Pumps and Telemecanique, among others. Young Shin’s devoted factory service and support programs have propelled the company into one of the world’s most prominent providers of superior die cutting and finishing solutions

The GIANT Series of Diecutters include:

Giant 130(S) and Giant 150(S)

Giant 170(S) and Giant 180(S)

Giant 190(S), 210(S) and 250(S)

Get in touch! Speak with John Harrison for consultation and pricing