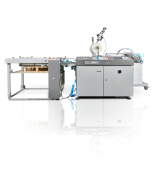

Komfi: Amiga 52 Laminator - Special Offer!

High Quality, High Speed Laminator - Up to B2 format.

ENQUIRE

The design of the Amiga B2 laminator meets all requirements for user friendly operation which makes the operator’s work easy. Available in several configurations combining different types of feeders, processing units, separation ways and output delivery.

Key Advantages

| Format | Laminator for processing orders up to B2 sheet format |

| Ideal Jobs | Suitable for digitally printed output |

| Volume | Flexible solution for processing of small as well as middle-volume jobs |

| Speed | Output: 4300 A4 sheets/hour (basic variant), 8000 A4 sheets/hour (feeding head) |

| Quality Control | Special functions to protect digital prints against damage |

| Paper Weights | Machine function to facilitate lamination of sheets in range 115-600 g/m2 |

Basic configuration

As Amiga 36 with the addition of NBR rubber pressure roll, automatic sheet separation using built-in perforator, a combined de-curling unit (bar and roller) and a tilting unloading table

'I laminate often, but mostly smaller jobs. I don’t need extra speed, but a reliable machine that can laminate a variety of mostly digitally printed jobs.'

If this is you, the Komfi Amiga 52 is an ideal solution! Our wide range of lamination solutions will have something to suit every requirement.

Please login to view price

SKU: Komfi: Amiga 52 Laminator-special-offer