WAB: DYNO-MILL UNI LAB Bead Mill

Laboratory Agitator Bead Mill

ENQUIREThe DYNO-MILL UNI LAB is a state-of-the-art laboratory mill designed for dispersion and fine grinding applications in research and development. Engineered for precision and efficiency, this compact bead mill delivers nanometer-range results across low- to high-viscosity products. With its versatile grinding principles, advanced DYNO-ACCELERATOR technology, and innovative DYNO-DISC BC system, the UNI LAB sets new standards for performance, scalability, and flexibility in laboratory milling.

Grinding Chamber Features

| Feature | Product inlet |

| Feature | DYNO-DISC BC (Bead Channel) |

| Feature | Grinding circuits that operate in opposite directions |

| Feature | Even distribution of the grinding media in the active grinding chamber |

| Feature | DYNO-ROTOR BS (Bead Separation) |

| Feature | Screen for high throughputs |

| Feature | Product outlet |

Specially developed for laboratory use, the DYNO-MILL UNI LAB offers exceptional flexibility and reliability for producing high-quality dispersions and ultra-fine grinding results down to the nanometer range. This compact agitator bead mill is engineered to handle a wide spectrum of products, from low to high viscosities, making it the ideal choice for research institutions, universities, and industrial laboratories.

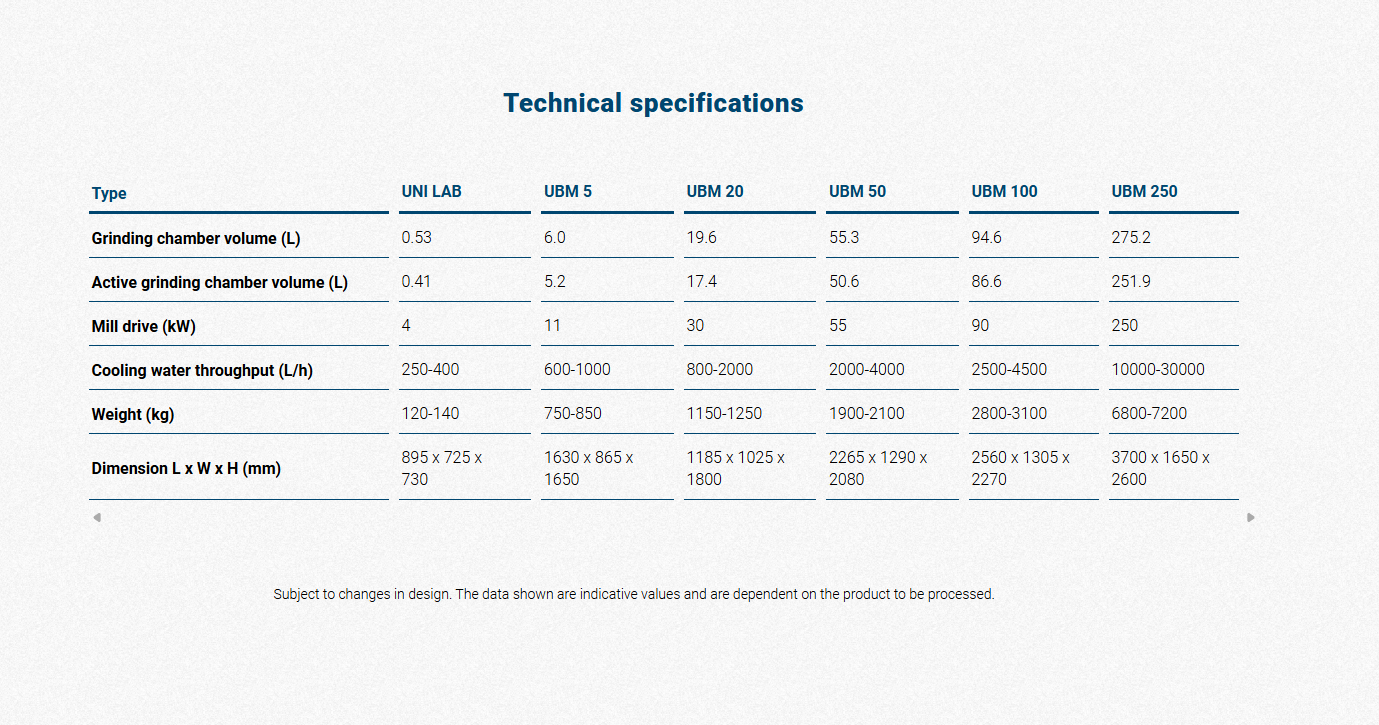

The UNI LAB supports two different grinding principles for maximum adaptability. In its standard version, it functions as a scale-up model for the DYNO-MILL UBM series, ensuring seamless transition from lab to production. For enhanced flexibility, the mill can be equipped with a second grinding chamber that utilizes the globally recognized DYNO-ACCELERATOR technology, delivering unmatched cost-effectiveness and process efficiency in laboratory environments.

At the core of the system is the newly developed DYNO-DISC BC (Bead Channel) technology. These advanced agitator discs feature unique grinding media channels combined with a closed outer contour, ensuring optimal energy transfer and highly efficient bead movement. The result is two counter-rotating grinding circuits that guarantee precise, consistent, and reproducible results.

With its combination of cutting-edge engineering and laboratory-friendly design, the DYNO-MILL UNI LAB provides a scalable, efficient, and versatile solution for R&D teams, universities, and industrial labs seeking consistent, high-performance grinding and dispersion results.

Why the DYNO_MILL UNI-LAB is superior:

- Suitable for high throughputs and highly viscous products

- Wide range of materials for optimum machine equipment

- Suitable for temperature-sensitive products thanks to effective cooling of the grinding chamber

- Suitable for steel, glass and ceramic grinding media

- Uniform grinding media density distribution in the grinding chamber for maximum efficiency

- Efficient grinding with grinding media from ø 0.2 mm (with a grinding chamber exchange unit DYNO-ACCELERATOR, grinding media from ø 0.1 mm can also be used)

- Long screen life

- Suitability for passage and circulation mode

- Simple and ergonomic machine handling including maintenance work

- Fast product changes

- Wide range of control solutions