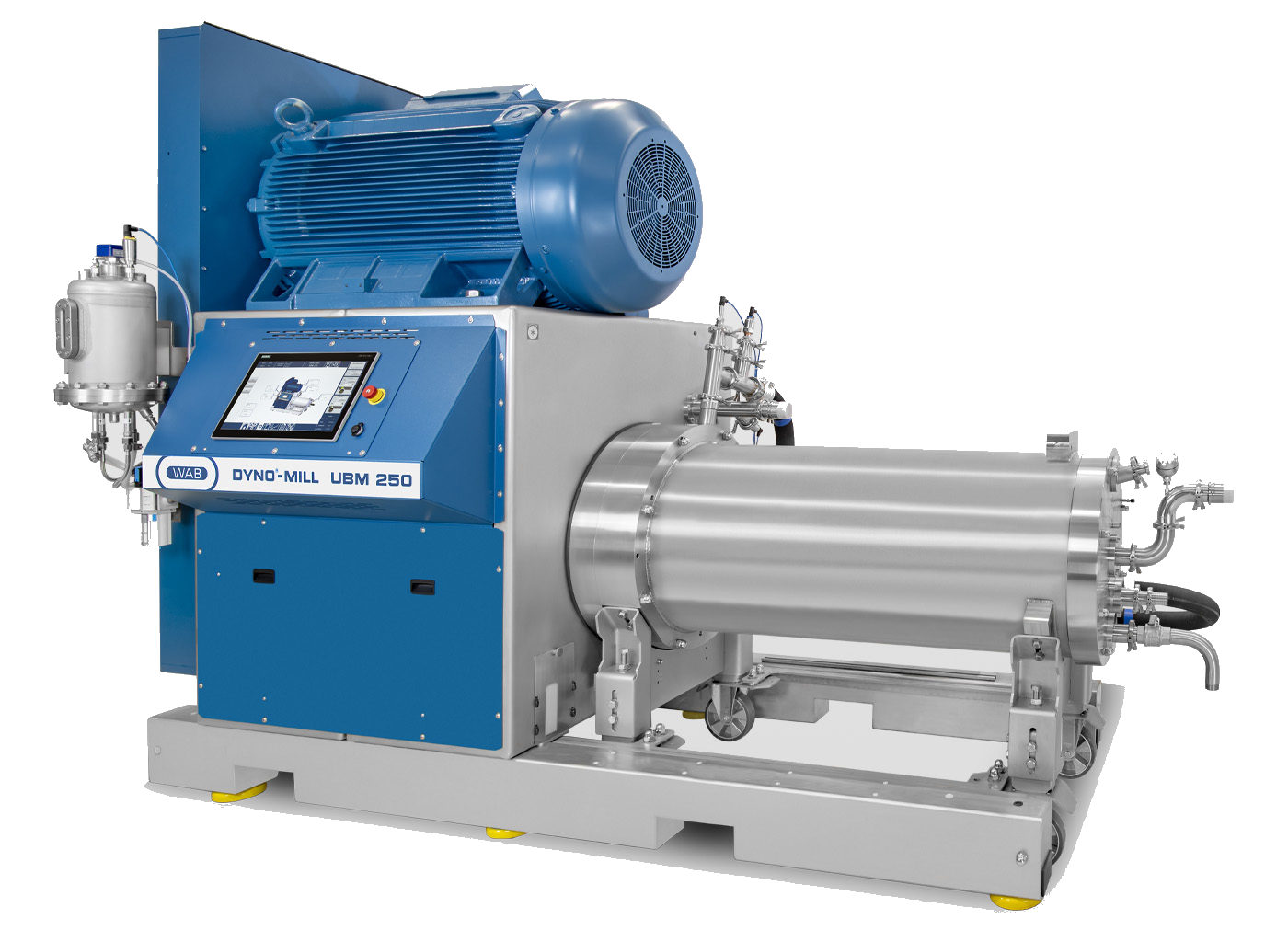

WAB: DYNO-MILL UBM 250

Efficient dispersion and fine grinding solutions for your products

ENQUIRENext-Generation WAB-GROUP Agitator Bead Mill

The DYNO-MILL UBM 250 has the largest grinding container volume in this series. It impresses with its high output, optimized efficiency and first-class performance for versatile applications.

The latest generation of the WAB-GROUP agitator bead mill is designed to handle the full spectrum of applications, from dispersion to ultrafine grinding. Whether for small-scale laboratory work or large-scale production, this advanced system ensures optimal performance across all volume requirements. Engineered for efficiency, reliability, and cost-effectiveness, this machine series meets the highest industry standards.

Advanced Functionality

At the core of this innovation are the newly developed DYNO-DISC BC agitator discs, specifically designed for this series. These discs feature precision-engineered grinding media channels and a closed outer contour, optimizing media acceleration along a well-defined path. Each grinding media channel generates two highly efficient grinding circuits, operating in opposite directions between the DYNO-DISC BC agitator discs. This cutting-edge design enhances processing efficiency, ensuring superior results in every application.

Features

-

Ergonomic Design: The grinding chamber is positioned at an ideal working height, facilitating quick and ergonomic cleaning operations. Upon opening, the grinding media are emptied into a durable stainless steel channel securely attached to the machine housing, allowing for easy transfer to other containers.

-

Durability & Low Maintenance: The high wear resistance of the DYNO-MILL UBM extends maintenance cycles, reducing overall maintenance costs. Coupled with the unmatched service from WAB-GROUP, this mill generation ensures excellent machine availability.

-

High Throughput & Viscosity: Ideal for high throughputs and handling highly viscous products, thanks to large screen passage areas.

-

Long Screen Life: The screens offer extended service life, reducing the need for frequent replacements.

-

Efficient Screen Change: Screen replacement can be done without opening the grinding chamber, minimizing downtime.

-

Flexible Operation: Suitable for both passage and circulation operations, ensuring versatile processing options.

-

Customizable Equipment: A broad selection of materials available to optimize machine configurations for specific needs.

-

Wide Range of Grinding Media: Compatible with grinding media sizes from 0.2 to 2.5 mm.

-

Flexible Chamber Volume: Available in grinding chamber volumes ranging from 0.5 to 250 liters.

-

Mechanical Seal: Features a low-maintenance, double-acting mechanical seal designed for the highest operational demands.

-

Closed Machine Housing: Ensures a sealed, safe operating environment.

-

Low Noise Operation: Designed to operate with a low noise level for a quieter work environment.

-

Comprehensive Control Solutions: A wide range of control options to suit various operational needs.