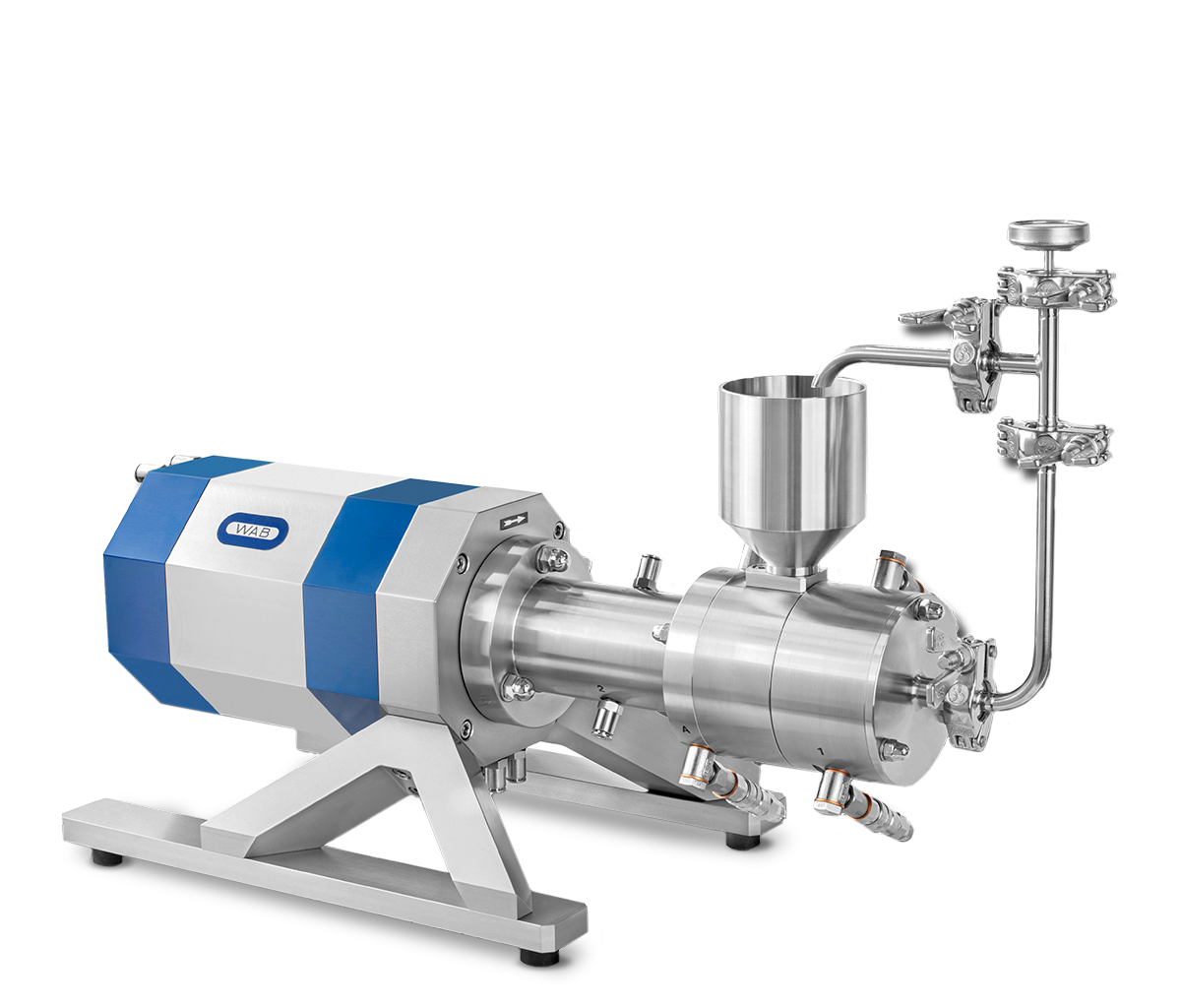

WAB: DYNO-MILL RESEARCH LAB Bead Mill

Special Agitator Bead Mill

ENQUIREThe DYNO-MILL RESEARCH LAB is the ideal agitator bead mill for laboratories and research departments that work with small sample quantities. With a grinding chamber volume of just 80 ml, this compact mill delivers reproducible results from as little as 100 ml of suspension. Easy to dismantle and quick to clean, it is perfectly suited for test series and fast product development in research environments.

Separation System with Self Cleaning

| Feature | Feed funnel 250 ml, 500 ml or 1000 ml |

| Feature | Product inlet |

| Feature | Seal housing for lip seal or double mechanical seal |

| Feature | Feed screw |

| Feature | DYNO-ACCELERATOR |

| Feature | Coolable grinding container |

| Feature | Cooling water inlet/outlet |

| Feature | Grinding media separator - sieve plate with gap widths for the use of grinding beads ø 0.05-1.0 mm |

| Feature | Product outlet |

The DYNO-MILL RESEARCH LAB is specially designed to meet the demands of R&D laboratories where only limited product quantities are available during initial synthesis stages. Traditional grinding tests often require more material than early-stage research can provide — this is where the RESEARCH LAB mill excels.

The suspension is introduced into the 80 ml grinding cylinder by a feed screw, ensuring a controlled and consistent feed. At the core of the system is the patented DYNO-ACCELERATOR, which transfers high energy to the grinding beads, enabling efficient particle size reduction. This technology allows researchers to achieve particle sizes in the nanometer range, often below 100 nm, depending on the application.

Grinding media are securely retained within the mill by a precision-engineered sieve plate at the product outlet, ensuring safe and reliable operation. The compact design makes the mill easy to dismantle, clean, and reassemble, reducing downtime between test series.

The DYNO-MILL RESEARCH LAB supports rapid product development by enabling realistic grinding conditions on a miniature scale. It is particularly beneficial for industries such as pharmaceuticals, cosmetics, specialty chemicals, and advanced materials, where reproducible results, small batch testing, and efficient scale-up are essential.