WAB: DYNO-MILL MULTI LAB Bead Mill

Laboratory Agitator Bead Mill

ENQUIREThe DYNO-MILL MULTI LAB is a versatile laboratory mill designed for exceptional flexibility in research, development, and small-scale production. This advanced lab mill allows easy variation of grinding chamber sizes, material options, and grinding technologies, making it the preferred choice for dispersing and comminuting materials across a wide range of viscosities and batch sizes. Whether in discontinuous or continuous operation, the DYNO-MILL MULTI LAB ensures reliable performance, precise results, and seamless scale-up to larger DYNO-MILL production systems.

Key Features

| Feature (discontinuous) | Coolable grinding container |

| Feature (discontinuous) | DYNO agitator disc |

| Feature (discontinuous) | Product inlet |

| Feature (discontinuous) | Product outlet |

| Feature (continuous) | Coolable grinding container with easily replaceable grinding cylinder |

| Feature (continuous) | DYNO agitator disc |

| Feature (continuous) | Product inlet |

| Feature (continuous) | Dynamic gap separator |

| Feature (continuous) | Product outlet |

| Feature (continuous) | DYNO-ACCELERATOR |

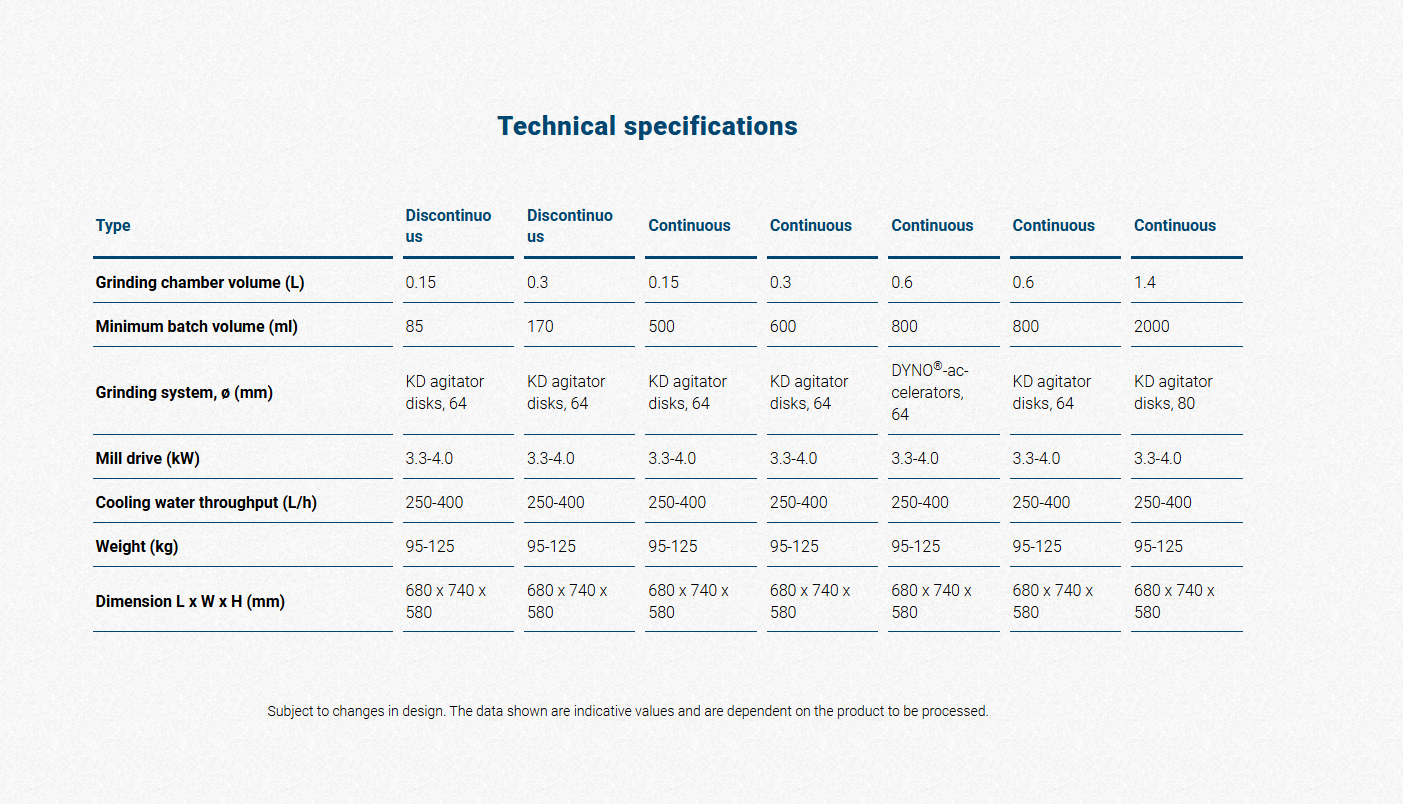

The DYNO-MILL MULTI LAB sets new standards in laboratory milling technology by combining flexibility, efficiency, and user-friendly operation. It is engineered for both research laboratories and small-scale production environments, offering outstanding adaptability with multiple grinding chamber sizes (0.15 l, 0.3 l, 0.6 l, and 1.4 l) and a wide choice of materials for contact parts.

Mode of Operation: Discontinuous Grinding

For small batch sizes of 85 ml and 170 ml, the DYNO-MILL MULTI LAB is equipped with specially designed grinding containers (0.15 l and 0.3 l). Ideal for low-viscosity suspensions, this configuration is widely used in microbiology for cell disruption and in pharmaceutical applications for processing active ingredients. After grinding, separation from the grinding media is performed via a washing step, ensuring product purity

- Proven grinding chamber system

- Coolable grinding container

- DYNO agitator disc

- Easy product inlet and outlet handling

- Mode of Operation: Continuous Grinding

For larger batch sizes starting from 500 ml, the mill offers continuous operation with containers ranging from 0.15 l to 1.4 l. A feed pump ensures efficient product flow, while the dynamic gap separator retains grinding media sized from 0.1 to 2.5 mm. For high-throughput applications, the patented DYNO-ACCELERATOR is available with the ECM grinding principle, supporting both circulation and passage modes (available in 0.6 l size).

System Highlights for Continuous Operation:

For processing low-viscosity to viscous, pumpable products with batch sizes >500 ml, grinding containers with a volume of 0.15 l, 0.3 l, 0.6 l and 1.4 l can be used. A feed pump positioned next to the mill is used to feed the ground material into the DYNO-MILL MULTI LAB. The grinding media are retained in the grinding chamber by means of a dynamic gap separator, which allows the use of grinding media with a ø of 0.1 to 2.5 mm.

The ECM grinding principle with the DYNO-ACCELERATOR is used for very high throughputs in the circulation mode, but also in the passage mode. This version is available in the 0.6 l volume size.

What makes the DYNO-MILL MULTI_LAB Superior?

- Flexible, coolable grinding container with replaceable cylinder

- DYNO agitator disc and dynamic gap separator

- DYNO-ACCELERATOR for maximum efficiency

- Easy product inlet and outlet control

- Key Features and Benefits

- Optimized for R&D and small-scale production

- Operates in both discontinuous and continuous modes

- Two grinding principles in one mill: DYNO agitator disc and DYNO-ACCELERATOR

- Direct scalability to all production-size DYNO-MILL systems

- Wide selection of materials for wear parts, including high-quality ceramics for metal-free grinding

- Long service life, minimal maintenance, and easy cleaning (GMP-compliant)

- Ergonomic, modular design for quick reconfiguration

- Excellent cooling properties for temperature-sensitive products

- Sophisticated and adaptable control systems