Find Blumer on stand E30-5, Hall 15

AG-4220

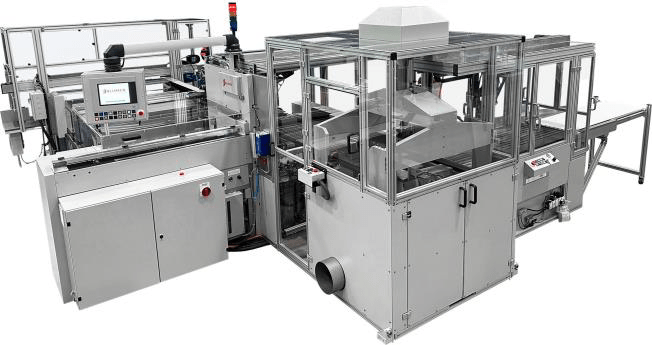

The new AG-4220 (another world first from Blumer) It is a fully automatic counter-pressure die-cutting machine, specially developed for processing large label formats.

It is the only counter-pressure die-cutting machine in the world that can precisely process large formats measuring up to 239mm x 420mm. With the help of counter-pressure, it is able to process multiple substrate types and materials up to 50 micrometers (microns). With the AG-4220, you can also look forward to maximum precision, reliability and the consistently high performance that characterize Blumer machines.

All work steps such as buffering, cutting, die cutting with counterpressure, separating and banding run fully automatically. It is suitable for medium production volumes as well as for small batches and is the only counterpressure die cutting machine in the world that can process large formats labels up to such dimensions.

Atlas-1110 DoubleStack (find it on the baumann stand)

After presenting the first new development in January – the ATLAS-1110 DS (Double Stack), with two strips/stacks being processed simultaneously for the first time (making it the fastest and most productive punching machine on the global market).

The ATLAS-1110 DS is the further development of our globally successful and proven ATLAS-1110 LS. Both are fully automatic die-cutting and banding machines for wet-glue labels in small to medium-sized formats. Buffering, stack cutting, die-cutting, separating and banding – the entire process runs fully automatically with consistently high performance, precision and production reliability. The ATLAS-1110 DS offers banding options for single packs or optionally also for maxi packs. For even better user-friendliness, the Atlas-1110 DS has completely new software and a new user interface.

Regardless of whether the machine is set up in-line or off-line with the upstream process, or the pre-cut strips are fed manually or using a gripper, the ATLAS-1110 LS offers maximum flexibility.

Atlas 40 with Maxi

A machine with a lot of potential for companies that cut their products in stacks with regular guillotines. Placed in-line with an existing cutting machine, the ATLAS-40 improves the cutting productivity in a very significant manner. Then the strips get moved individually, or as an entire load onto the in-feed table of the Atlas-40.

The rest of the process is then fully automatic. Buffering, separating into 1-4 strips (depending on the strip width), cutting, intermediate cuts and finally banding on 1-4 stations. The optional maxi-pack banding module enables four bars to be banded simultaneously. This allows our customers to further increase the efficiency of their production and significantly optimize the cutting and banding of rectangular labels in large quantities.